Student organizations collaborate to create 3D-printed PPE for hospitals

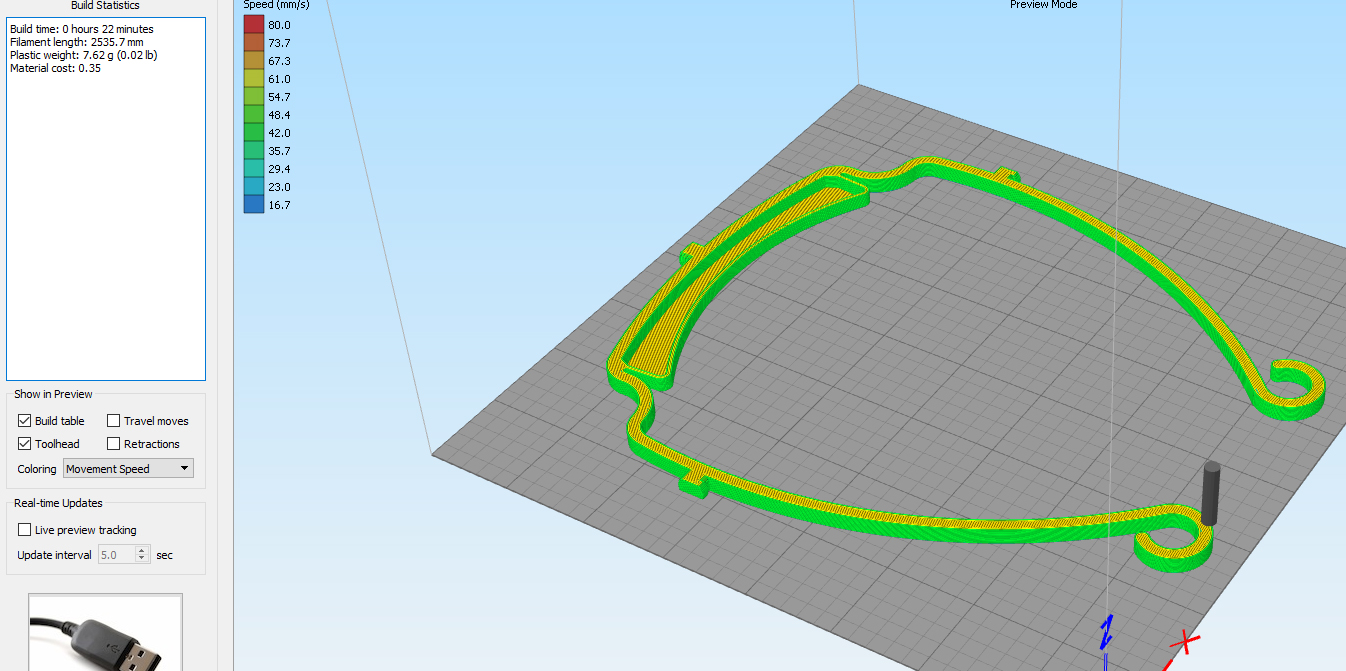

Two UCLA student organizations are working to design and 3D print personal protective equipment in light of shortages arising from the COVID-19 pandemic. (Courtesy of Kyle Ho)

By Priscilla Guerrero

May 4, 2020 9:48 p.m.

Two UCLA-based student organizations are working together to 3D print personal protective equipment, or PPE, for local hospitals across California, New York and Rhode Island.

The novel coronavirus pandemic has caused shortages of PPE for health care professionals across the nation, leaving medical workers without the necessary protection or having to reuse PPE.

3D4E, a 3D printing organization at UCLA, is training participating members how to produce PPE using 3D printers, said Ryan Tong, the tech advisor of 3D4E and a second-year computer engineering student at UCLA.

The group is working to produce the equipment with AIRES, or the AI Robotics Ethics Society, a nonprofit organization formed at UCLA for the purpose of discussing and disseminating information about the ethics of artificial intelligence. The project receives funding support from a GoFundMe page started by AIRES at the beginning of April.

AIRES started the GoFundMe page with the goal to raise $15,000 in order to create at least 10,000 face shields, said Aaron Hui, the president of AIRES and a fourth-year computational and systems biology student at UCLA. AIRES and 3D4E will use the funds to buy 3D printers and other necessary materials to assemble the PPE.

Although the initiative doesn’t concern AI ethics, Hui said the group still wanted to help.

“When we realized that there’s a shortage of PPE materials, we really wanted to make a difference,” Hui said. “While we didn’t really have that much experience in this area, we knew that we had the infrastructure and we also have the connections to make this possible.”

The group has chapters at UCLA, USC, Cornell, Caltech, Stanford and Brown University, and are using their network to make their new endeavor possible, Hui added.

The GoFundMe has raised more than $4,300 so far, which the team is using to produce hundreds of face shields for hospitals, Hui said. When there is no longer a need to print PPE, the 3D printers will be donated to their respective universities.

Though the members of AIRES and 3D4E are assembling the face shields separately, they are constantly communicating with each other to solve any problems that might occur, Tong said.

“3D4E has been kind of doing more of the technical things, helping out those who have never touched 3D printers before with support or advice, and we’ve been recommending what kind of filament to use and just some of the material logistics.”

The face shields are made using the Swedish 3DVerkstan model, which is a National Institutes of Health-approved design for the 3D-printed headband. The members are also using Fused Deposition Modeling 3D printers along with PETG filaments, material that is both durable and flexible, to print the plastic headband. PVC binding covers and a three-hole puncher are then used to attach the plastic sheet to the headband to create the shield, Hui said.

The members are taking extra precautions when assembling the shields, wearing their own masks and gloves, Hui said. Once the face shields have been made they are left alone for three days to disinfect and are then delivered to local hospitals personally or by mail, he added.

Respirators and N95 masks, which filter around 95% of airborne particles, are a more effective form of protection, but 3D printed face masks do not ensure the N95 quality that hospitals typically require, Hui said.

“We’re 3D printing what we can, which is face shields, and it’s still an extremely vital piece of equipment. Respirators and N95 masks, while they are extremely important, they’re just part of the protection – the whole face has to be protected, not just the nose or the mouth,” Hui said.

Leila Kim, president of AIRES at Brown University and a second-year computer science student, has never used a 3D printer before but believes the process won’t be too difficult.

“If we need help we can contact (3D4E) and they’ve been very helpful with providing files and giving tips about … printing the most quickly,” Kim said. “I was a little intimidated by having to learn how to 3D print but it actually seems like I’m in good hands.”

Though 3D printing is outside of AIRES’s area of interest, Hui said the group was reminded why they got involved with AI ethics amid this pandemic.

“We couldn’t foresee (COVID-19), but it’s already threatening our loved ones much sooner than any unethical AI possibly can,” Hui said. “What we realized was we don’t have to be medical professionals. We don’t have to be doctors, nurses or anything like that. … When we help our health care providers and keep them safe, they in turn can help save our loved ones.”