By Andrew Arifin

May 9, 2017 4:25 p.m.

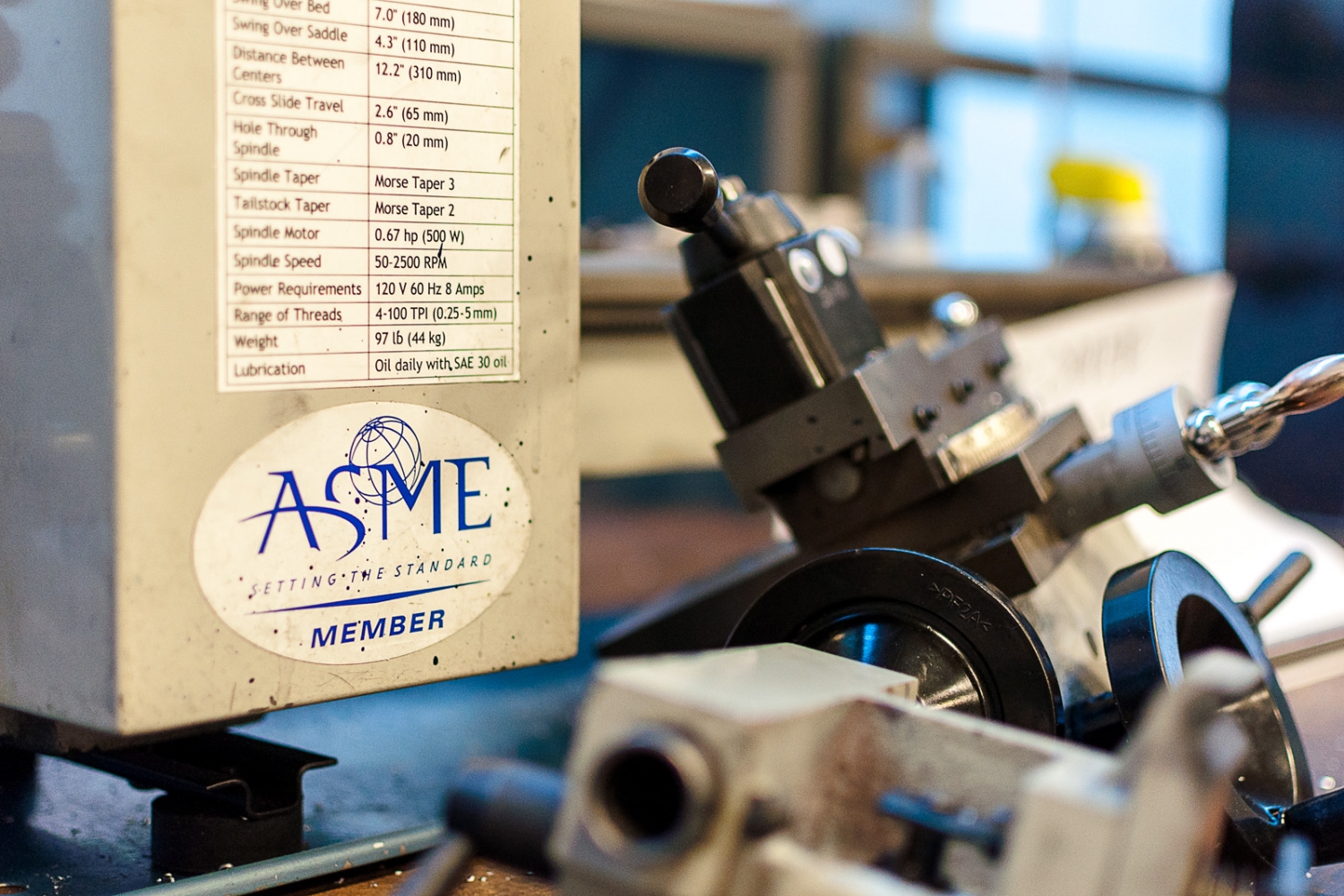

The American Society of Mechanical Engineers is the premier student organization for all things mechanical engineering. Through various projects like the FADE Training Program, the BattleBots Projects and the X1 Robotics Initiative, it hopes to help students grow through both project-based and professional initiatives. This year, ASME took on a huge project to create the Chemical Utility Bot, a mobile robotic platform designed to remotely survey areas affected by hazardous materials.

(Andrew Arifin/Daily Bruin)

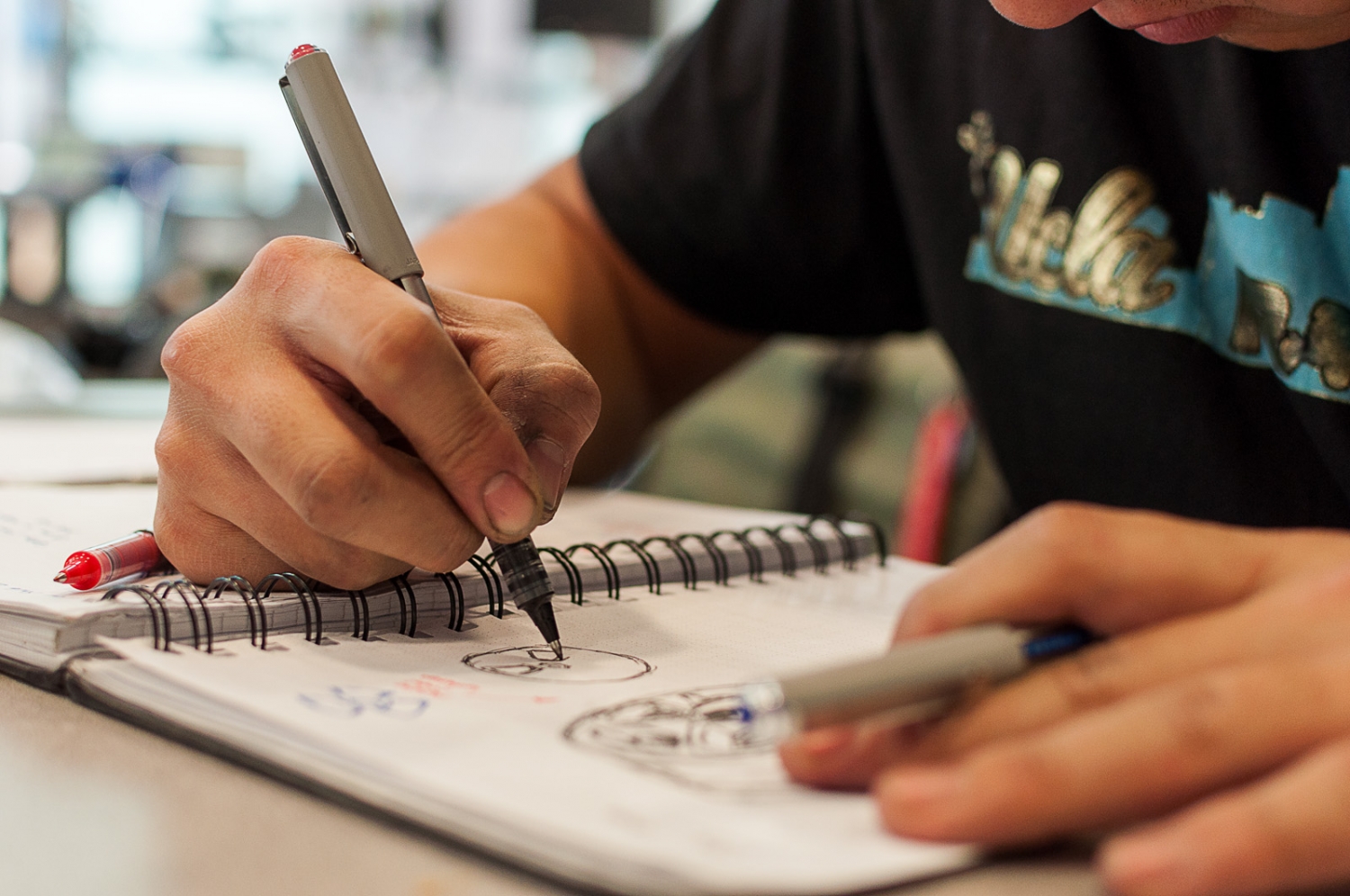

Sean Oh, the president of ASME, works on some sketches of the final product. A fourth-year mechanical engineering student, he is spearheading this project. ''For me, being a mechanical engineer meant being able to fully understand and appreciate the physical world around me,'' Oh said. ''Many things that we interact with in our daily lives are often overlooked and taken for granted, but with the knowledge of how something works, how it was made, and why it’s designed the way it looks, we gain a new perspective on virtually everything in the world. Taking advantage of this realization allows us to make improvements, create novel innovations, and ultimately build our world into anything we aspire it to become.''

(Andrew Arifin/Daily Bruin)

From rough sketches to digital mock ups, extensive planning is done before the actual machining starts. Mechanical engineering is a discipline that requires precision and an extreme attention to detail.

(Andrew Arifin/Daily Bruin)

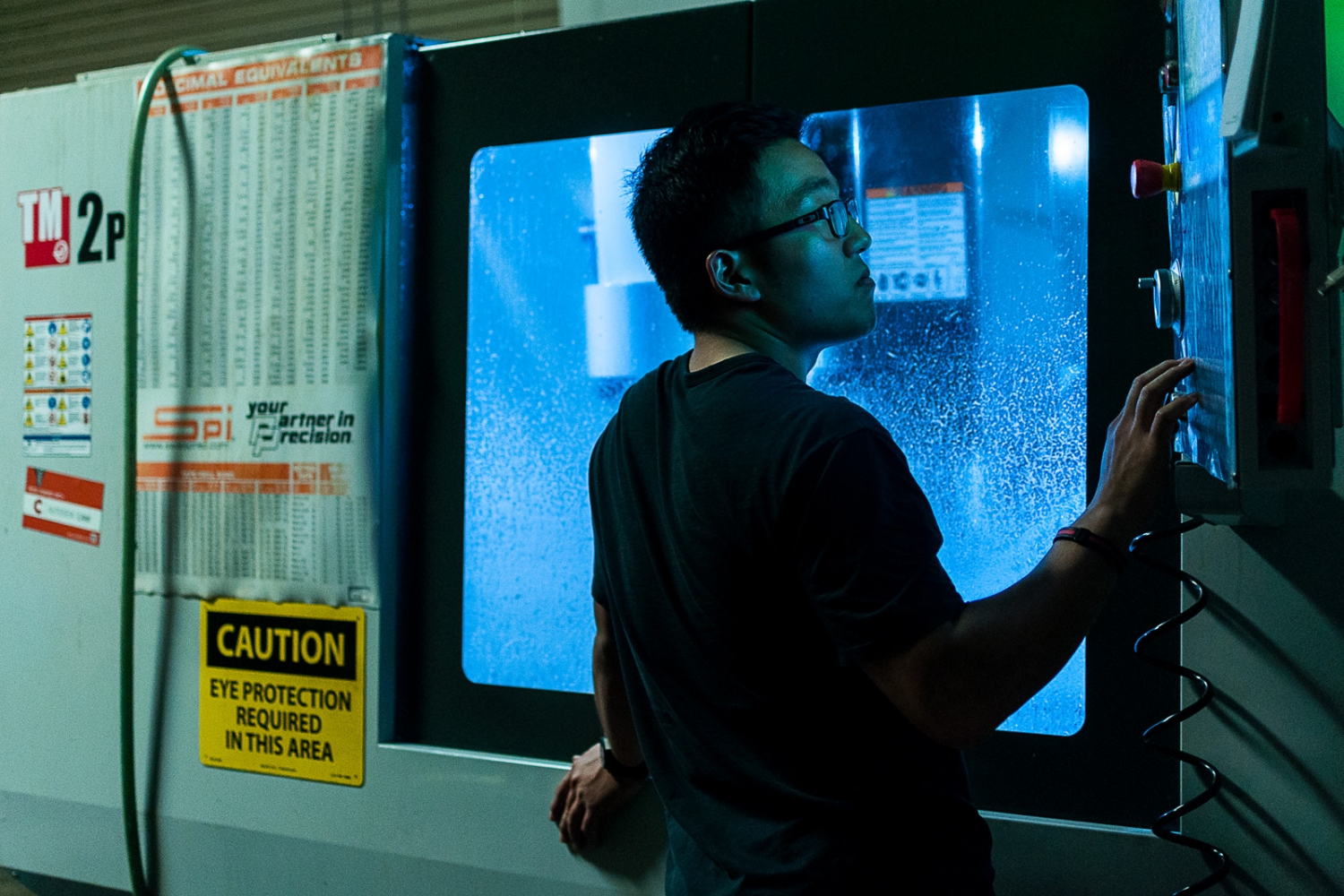

Kevin Chang, a long time member of ASME, cleans up a part of the C.U.B.

(Andrew Arifin/Daily Bruin)

Oh monitors the computer numeric control vertical mill as it manufactures one of the parts of the C.U.B. The CNC vertical mill is used to create the complex parts of the C.U.B. Once programmed, it is capable of fully autonomously manufacturing high precision parts with complex 2-D and 3-D features from a variety of materials. It is essentially a robot making parts of another robot.

(Andrew Arifin/Daily Bruin)

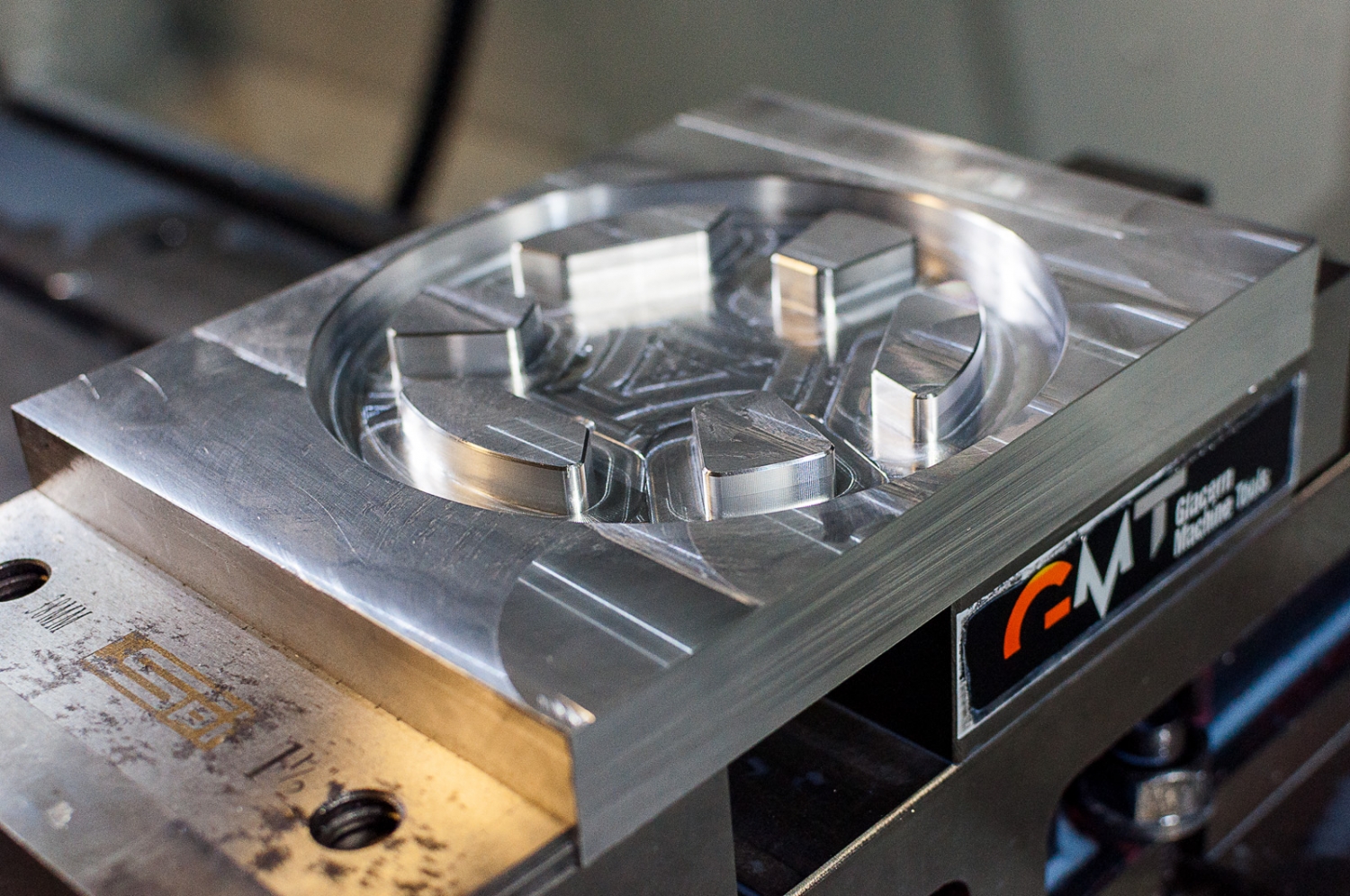

The CNC vertical mill in action as it machines one of the parts of the C.U.B.

(Andrew Arifin/Daily Bruin)

Despite the precision of the CNC machine, it is very important to inspect and clean the part after it is complete.

(Andrew Arifin/Daily Bruin)

The final product after approximately 30 minutes of machining shows the precision and detail that the CNC vertical mill is capable of.

(Andrew Arifin/Daily Bruin)

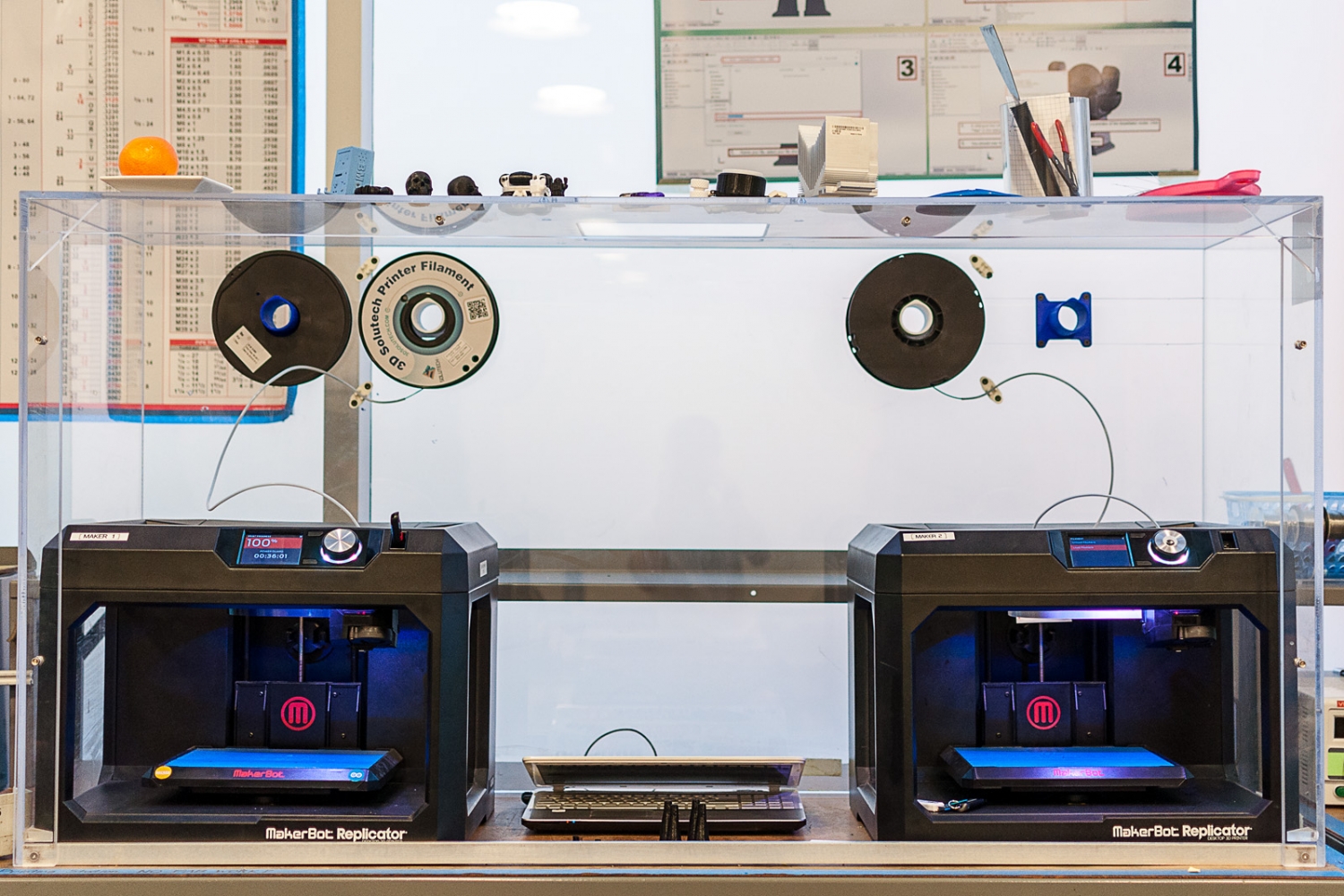

Much of the robot was 3-D-printed with these two printers. 3-D-printing has greatly cut down the time and cost that used to hamper projects like this.

(Andrew Arifin/Daily Bruin)

On track to be complete by the end of this quarter, the C.U.B is slowly taking shape. With a special chassis constructed of highly chemically resilient polymers and metals, the C.U.B can be deployed in situations much more easily than a human, reducing cost and response time.